Product Development Performance Measurement

Lorem ipsum dolor sit amet adipiscing elit.

All manufacturing companies must have an effective Product Development (PD) process model. This model functions as the operating system that enables a company to transform ideas into profitable, manufacturable, and innovative products that address real customer and market needs. Without a formal PD model, product development becomes reactive, fragmented, and driven by individuals rather than by a disciplined, business-controlled process.

In manufacturing organizations, product development is where most cost, quality, and market success are determined. Research has consistently shown that up to 80 percent of total manufacturing cost is committed during the conceptual design stage. Decisions made at this early phase also strongly influence product sustainability, including circularity, reuse, and remanufacturing potential. Once these decisions are locked in, they are extremely costly or impossible to change later.

For this reason, manufacturing companies are encouraged to invest in Product Development Performance Measurement. This is the systematic process of evaluating the efficiency, effectiveness, and capability of product development activities, processes, and systems against defined targets. By measuring performance, organizations gain the insight needed to improve decision-making, reduce risk, and consistently deliver high-value products to the market.

The ”Digital Lean Exchange” offers services of Lean Product Development Performance Measurement based on a tool that was developed and texted in many companies.

LeanPD Performance Measurement Tool Overview

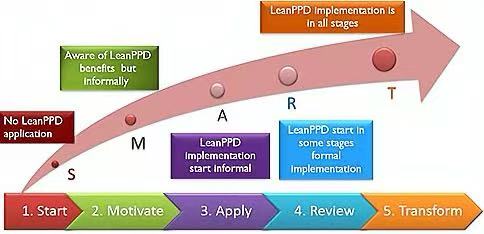

The assessment framework to evaluate LeanPD organisational readiness and maturity is the industry-validated SMART Scale Performance Measurement Tool shown in Figure 1 . The Tool employs a structured, five-step SMART scale methodology that enables clear and objective evaluation of the current state, whilst providing progression pathways towards a desired future state appropriate for the organisation under review.

Figure 1The Lean PD Performance Measurement; The SMART Scale LeanPD journey

The LeanPD Performance Measurement Tool encompasses four domains or perspectives that consider collectively represent the foundational elements of successful LeanPD deployment. The four domains are equally weighted, providing the company with a balanced, quantitative perspective on an organisation’s current state capability whilst identifying specific focus areas suitable for targeted intervention.

Key Assessment Domains

PD Process

- Considers the maturity and effectiveness of the company’s current PD process(es).

Tools / Enablers

- Assesses the availability, deployment, and integration of LeanPD techniques and supporting technologies across the PD lifecycle.

Knowledge / Focus

- Evaluates the extent to which the organisation captures, shares and utilises intellectual capital developed during PD activities across the full lifecycle.

People and Skills

- Addresses the human perspective of successful LeanPD deployment

- Particularly workforce competence and cultural readiness for the systemic organisational change required for effective implementation.

LeanPD SMART Scale Definitions

The resultant ‘as-is’ and ‘to-be’ scores from the assessment are positioned on a 5-point ‘SMART’ scale as defined below:

| SMART Scale | Definition |

|---|---|

| Start | The company does not apply the lean practice in its Product Development Process (PDP). |

| Motivate | The company is aware of the benefits brought by the lean practices but does not have any formal method to implement it. |

| Apply | The company has just started to apply the lean practices in its PDP following an informal method. |

| Review | The company has implemented the lean practice in PD Process at some specific stages following a formal method. The results are being reviewed and analysed. |

| Transform | The company has implemented the lean practices in all the stages of the PDP following a formal method. |

How the LeanPD Performance Measurement Tool Is Applied

The LeanPD Performance Measurement Tool is designed to assess an organization’s readiness for its Lean Product Development (LeanPD) transformation. The following guidelines describe how the tool should be applied to ensure reliable and meaningful results.

Participant Selection: It is recommended to involve a group of at least five representatives from different departments to capture a balanced, cross-functional view of the organization.

How Participants Complete the Assessment: Each participant should complete the assessment based on their own experience, responsibilities, and daily practices, not on assumptions about how the company operates overall. The assessment typically takes about one hour per participant.

Participant Briefing

Before starting, participants receive a short presentation that introduces:

- The principles of Lean Product Development

- Key LeanPD tools and methods

- The structure and purpose of the assessment tool

This ensures a common understanding and increases the reliability of the responses.

Ways to Apply the Tool

The LeanPD DT Performance Measurement Tool can be administered in one of the following ways:

- Individual interviews: Conducted face-to-face or online via video call, with each participant interviewed separately.

- Facilitated group session: Participants meet in one room and complete the questionnaire individually, either using an electronic form or a paper-based version.

Both approaches ensure independent responses while allowing efficient data collection.

LeanPD Performance Measurement Results

After all responses have been collected, The Digital Lean Exchange analyses the data and provides a detailed performance report within two weeks. This report highlights the organization’s current LeanPD maturity, strengths, and improvement opportunities to support its transformation journey.