IoT two days short course

Internet of Things (IoT) Network: Fundamental knowledge and Practical skills

COURSE BRIEF

This course provides a comprehensive introduction to the fundamental concepts and practical working knowledge of Internet of Things (IoT) network principles, tools, techniques, and applications. It is specifically designed to address long-standing operational challenges in manufacturing and to enhance productivity, efficiency, and product quality.

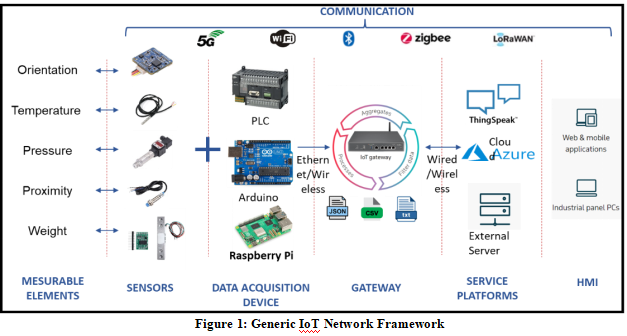

Participants will gain a clear understanding of why IoT technologies are essential for modern manufacturing environments. The course covers the complete IoT system lifecycle, from network design to implementation, structured across the key architectural layers of an IoT solution. Topics begin with identifying measurable parameters of products and machines, followed by the selection of appropriate smart sensors and data acquisition devices. The course then progresses to IoT gateways, cloud-based service platforms, and the development of user applications for data visualization, monitoring, and operational feedback.

In addition, the course provides practical coverage of data communication protocols and the programming of both hardware and software components of the IoT Network. Emphasis is placed on hands-on learning to ensure participants can confidently design, build, and deploy functional IoT systems.

Participants will be provided with Raspberry Pi devices, a variety of sensors, breadboards, wiring components, and access to cloud computing platforms to support a range of practical Hands-on exercises.

NOTE: All participants are expected to have Basic laptop skills recommended. Participants should bring a laptop with admin rights (or provide a pre-configured USB/VM option).

COURSE OUTCOMES AND OBJECTIVES

Upon successful completion of this short course, participants will be able to:

1. Understand the key enabling technologies of Industry 4.0 and their role in modern manufacturing and industrial environments.

2. Critically evaluate the current and future maturity of digital technology practices within an organisation.

3. Understand how IoT can address long-standing operational challenges while enhancing quality, productivity, and innovation.

4. Design and implement end-to-end IoT networks, including hardware, software, and communication protocols.

5. Gain practical, hands-on experience in selecting, programming, and integrating sensors, Raspberry Pi, IoT gateways, and cloud computing platforms.

6. Develop a strong understanding of building IoT applications using open-source software and tools.

7. Apply IoT and digital technologies to support digital transformation initiatives within their organisation.

Who should attend?

- This course is ideal for professionals and students involved in manufacturing, engineering, and digital transformation who want to gain practical IoT skills for Industry 4.0.

- It is particularly suitable for product designers, manufacturing, automation, electrical, and industrial engineers; maintenance and reliability engineers; IT and OT professionals; production and operations managers; quality and continuous improvement specialists; and digital transformation or innovation leads.

- The course is also well suited to engineering students and early-career professionals seeking hands-on experience with IoT technologies in real manufacturing use cases.

Course Details

II. Payment is advanced.

Course Content

DAY ONE

IoT Fundamental Knowledge – ½ Day

- Digital Transformation Performances measurement exercise.

- Key definition of digital transformation processes.

- Overview of industry 4.0 – The key element of industry 4.0.

- Introduction to IoT network in Industry:

- The definition of the measurable elements of the product/machine.

- The selection and installation of the suitable smart sensors.

- The selection and programming of the Data Acquisition Device/ Raspberry Pi.

- The connection of smart sensors with the Raspberry Pi.

- The IoT Gateway: installation and connection with the Data Acquisition Device.

- The conversion of the digital data into human-readable and machine-manageable formats, including JSON, txt, or CSV files.

- Data processing and storge in Service Platforms of cloud computing

- The development of user applications for data visualization & operational feedback to the IoT-based product/Machine.

The IoT Hands-On Exercises ½ Day

5. Basic electronic components and schematic reading

-

- Identify and use key components (resistors, LEDs, buttons, sensors, transistors/relays as applicable)

- Understand breadboard layout and safe wiring practices

- Read and draw simple circuit schematics for IoT prototyping

6. Basic Python programming for IoT

7. Working with sensors – Connecting sensors to Data Acquisition Device/ Raspberry Pi.

8. Working with actuators – Driving actuators safely (LEDs, buzzers, relays, small motors)

DAY TWO

Build an End-to-End IoT Network

- Building the sensor node – Assemble a sensor node integrating sensors + actuator(s) on Raspberry Pi.

- Connectivity and cloud/server integration – Connect the sensor node to the local network and cloud.

- Client and server programming – Implement server/cloud code to receive, store, and respond to received data from sensors.

- Two-way messaging and closed-loop control – Send commands from server to device (e.g., turn an actuator ON/OFF)

- Live demo of IoT network application